H2020 Smartmushroom Project: Smart management of spent mushroom substrate to lead the mushroom sector towards a circular economy

- Type Project

- Status Filled

- Execution 2018 -2021

- Assigned Budget 2.264.143,13 €

- Scope Europeo

- Main source of financing Horizon 2020

- Project website Smartmushroom

The Consortium has achieved the project objectives, and all tasks have been completed according to the Grand Agreement. ASOCHAMP-CTICH has coordinated the entire project at the administrative and financial levels, as well as the partners' tasks. They have obtained all the legal permits for the construction and installation of the pilot plant, as well as the registration of fertilizers and trademarks. In addition, fertilization trials have been conducted under their supervision in Spain. Asochamp has also contributed to the proper functioning of the pilot plant, supervising the installation tasks and daily operation, with the support of Sustratos de La Rioja.

NOVIS designed and installed the anaerobic digesters to build the biogas plant and carried out the necessary commissioning and commissioning work. As a result, the pilot plant generates biogas using SMS as a substrate. They also designed the best co-substrate mixes to feed the digesters.

IDECAL designed and installed a rotary dryer that uses the generated biogas to dry the SMS. The installation was completed and tested, resulting in the drying of the material through biogas combustion. The connection between the biogas plant and the dryer was supported by these two partners. Thanks to these preliminary actions, the consortium was able to produce SMS-based pellets.

ECOBELIEVE has conducted several trials to validate the fertilizing effect of the SMS-based pellets obtained through the project. The trials were carried out in open fields and greenhouses, on various crops, and yielded very valuable results, as there are clear and rapid benefits to using Smartmushroom fertilizer.

We have presented the project at various international fairs, where key stakeholders and end users from around the world have been informed about Smartmushroom. Our website and social media have supported online dissemination efforts to enhance visitor understanding. In addition, we have attended various conferences, seminars, workshops, and industry events, and have published in relevant R&D journals and websites, increasing our impact on the scientific field (fertilization, circular economy, anaerobic digestion), the agricultural sector, and the general public. To support the commercialization plan, an Augmented Reality app has also been developed so that interested parties can view the pilot plant as a mitigation measure against the implications of the COVID-19 pandemic.

Livestock and agricultural waste are the raw material for mushroom cultivation substrates. To grow one ton of mushrooms, three to four tons of substrate are needed. However, once mushroom production is complete, the substrate cannot be used for another cultivation cycle due to the depletion of the nutrients necessary for cultivation. Therefore, it is called Spent Mushroom Substrate (SMS), which constitutes waste that must be managed in accordance with current regulations.

In Europe, approximately 3.65 million tons of SMS are generated annually. SMS is a bulk material with high moisture content, rich in organic matter and nutrients, and could be reused in agriculture by adding it to the soil as an amendment or mulch, or by weathering it for reuse as a cover soil. However, the Nitrates Directive sets a landfill limit that prevents large quantities of SMS from simply being spread on the ground next to growers' facilities, as there is a high risk of leachate and water pollution. Due to its low bulk density and high water content, transportation costs are high, making storage a challenge.

We have demonstrated the feasibility of producing biogas using SMS as a digester in a pilot plant. The feasibility and technological maturity of the SMS-ADryer plant are fully demonstrated, as the biogas plant is operational and producing biogas, the dryer burns biogas to dry SMS, and this dried SMS is pelletized. Furthermore, SMS pellets have been tested and validated as an organic fertilizer through trials on various crops in greenhouses and open fields, comparing them in different mixtures with traditional fertilizers. Based on the yields obtained and plant growth, the viability and effectiveness of SMS pellets as fertilizer have been demonstrated, and the pelletized fertilizer trademark has already been registered.

The Smartmushroom project has generated significant interest among numerous mushroom grower associations, and we are in contact with several companies interested in acquiring the SMS-ADryer plant. The business case developed demonstrates the viability of the process, with significant social impact, as increased profitability for agricultural businesses translates into a greater number of residents in rural areas, job creation, and increased economic sustainability for the agricultural sector.

Livestock and agricultural waste, specifically horse and chicken manure and wheat straw, constitute the raw material for mushroom growing substrate. To grow one ton of mushrooms, 3 to 4 tons of substrate are required. However, once production is complete, the substrate cannot be used for another growing cycle due to the depletion of the nutrients necessary for its growth.

It's called Spent Mushroom Substrate (SMS) and is a waste product that must be managed in accordance with current regulations. In Europe, approximately 3.65 million tons of SMS are generated annually. SMS is a bulk material with a high moisture content, rich in organic matter and nutrients, which could be reused in agriculture by adding it to the soil as an amendment or mulch, or by weathering it for reuse as a cover soil.

However, the Nitrates Directive establishes a landfill limit that prevents large quantities of SMS from being spread on the ground near producer facilities, as there is a high risk of leachate and water pollution. Due to its low bulk density and high water content, transportation costs are high, making its storage a problem.

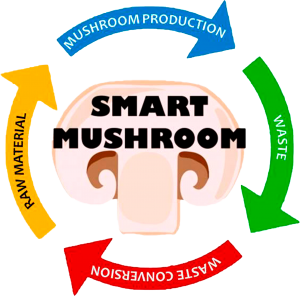

SmartMUSHROOM aims to increase the efficiency of mushroom growers' waste management through a new technology that enables them to obtain sufficient biogas from fresh SMS to dry and pelletize a mixture of digestate and additional fresh SMS, with the aim of obtaining a high-quality, marketable organic fertilizer rich in organic matter and nutrients, easy to handle, store, and transport to any agricultural region in Europe.

A perfect example of a bio-based circular economy. The project's objective is to build a pilot plant to demonstrate the technology and find the best commercial formulation for the pellets, with the aim of introducing them to the organic farming market. Upon completion of the project, at least 18 treatment plants are planned to be built, which will market 153,000 tons of SMS pellets, generating a total turnover of €54 million between 2021 and 2025 and up to 105 new related jobs.

SMARTmushroom is revolutionizing mushroom production with its proven SMS-ADryer, which converts currently cost-intensive mushroom production waste (SMS) into organic agricultural fertilizer, thereby increasing profits for producers. SMARTmushroom redefines the current extractive mushroom production model ("harvest, produce, dispose") into a circular economy model, decoupling it from the consumption of finite resources and eliminating waste from the system.

We have developed and built a 100- to 150-kW SMS-ADryer pilot plant and designed it for industrial scale, enabling the conversion of 36,000 tons of fresh SMS material per year. SMS is first digested using a two-stage anaerobic digestion process. The resulting biogas provides thermal energy, which is used in a water removal system based on a hybrid drying process that combines condensation and adsorption to accelerate the process and reduce costs. As a result, farmers using SMS-ADryer will reduce storage and transportation costs, enabling them to sell a new organic product suitable for conventional transport to any region in Europe.

SMARTmushroom enables the creation of a new, sustainable value chain, from processing to transport and application, encompassing both animal husbandry and mushroom cultivation. We are introducing the circular economy by transforming SMS waste into a high-value organic fertilizer (€90–140/ton). EU industry will gain an innovative solution to an unsolved global problem, strengthening its competitiveness. Society will benefit from this nutrient-rich product at lower prices, and the environmental impact of mushroom production will be lower, as SMS will be recycled into organic fertilizer through a carbon-neutral process, where no harmful compounds are released. The organic fertilizer will improve crop yields by at least 12% thanks to its low moisture content (28%).

We address the EU's low-carbon economy challenges through carbon capture—achieved in a natural, cost-effective, and environmentally friendly way—offsetting emissions from fossil fuel combustion, waste reduction, a circular economy, improved resource efficiency, and agricultural and rural development. This empowers mushroom-growing communities, increases their profit margins, boosts employment, and contributes to a more efficient and competitive agricultural sector.

Each SMARTmushroom plant, processing an average of 36,000 tons, will save between €216,000 and €360,000, generating an additional revenue of approximately €850,000 through the sale of pellets for organic farming. With the SMARTmushroom solution, mushroom producers will increase their profits by 25%.

- ASOCIACION PROFESIONAL DE PRODUCTORES DE SUSTRATOS Y HONGOS DE LA RIOJA NAVARRA Y ARAGON (ASOCHAMP)